In today’s highly competitive industrial landscape, success is no longer defined solely by production capacity or cost-efficiency. Instead, the ability to manage data, streamline operations, and adapt swiftly to changing demands has become essential.

As a leading manufacturer of diverse rubber compound formulations, our company, Zeon Advanced Polymix Co.,Ltd. has embraced this shift by implementing an integrated approach to digital transformation — combining a powerful Enterprise Resource Planning (ERP) system with Artificial Intelligence (AI) technology.

This strategic integration is not merely a technological upgrade, but a rethinking of how precision, traceability, and quality assurance are embedded into every step of our operations.

With a clear objective to enhance production precision, reduce operational loss, and elevate end-to-end quality control, our company has adopted an integrated approach by combining ERP (Enterprise Resource Planning) with AI (Artificial Intelligence) to manage data and analyze processes across every dimension of our manufacturing operations.

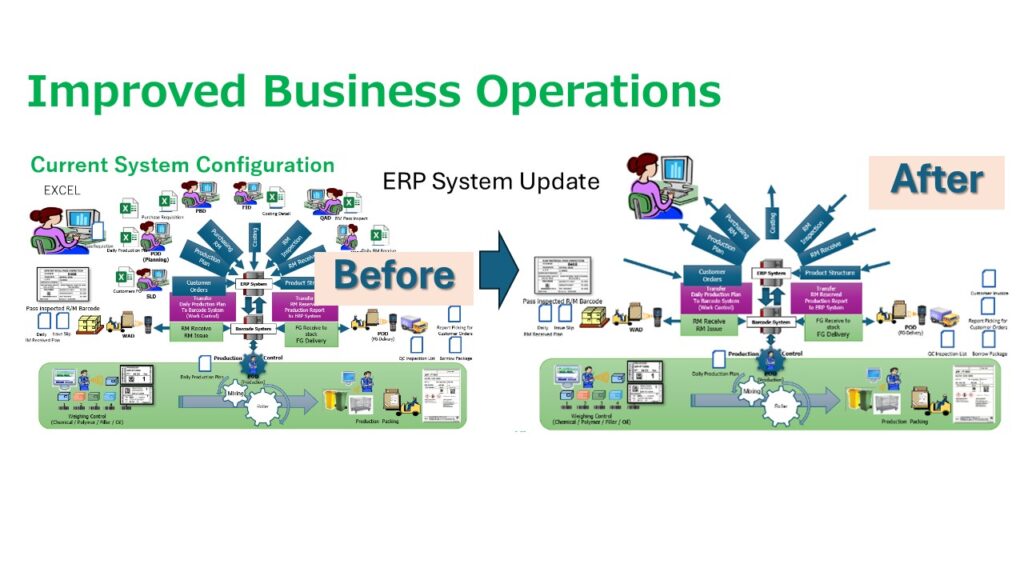

ERP System: The Backbone of Production Control

Our current ERP system encompasses the full production lifecycle — from production planning, raw material procurement, inventory management, and dispensing, to manufacturing execution, quality assurance, and product delivery.

This comprehensive system enables us to:

- Monitor production data in real-time

- Minimize errors caused by duplicate or manual data entry

- Seamlessly connect interdepartmental data for smooth collaboration

- Achieve full traceability of every production batch

AI: The Analytical Assistant

We have also developed and implemented AI technology to support in-depth production data analysis, including:

- Evaluating formula deviations across rubber compound batches

- Predicting process anomalies before they impact quality

- Analyzing temperature, timing, and mixer parameters to optimize production tuning

- Reviewing historical quality data to refine formulations and minimize waste

AI is not here to replace human expertise — it serves as a powerful tool that empowers our teams to make informed decisions backed by data.

What was once reliant solely on personal experience and manual observation is now augmented by AI-powered insights at every stage of production.

Our company remains fully committed to continuous improvement — not just through technology, but also by training personnel, developing new SOPs, and enhancing our internal communication systems. This ensures that:

“Everyone uses the system, and the system works for everyone.“

From a single batch of rubber compound to a systemized standard of manufacturing,

we are moving forward with purpose and precision in the era of Industry 5.0.